AERO–EXPERIMENT

Four runs were performed:

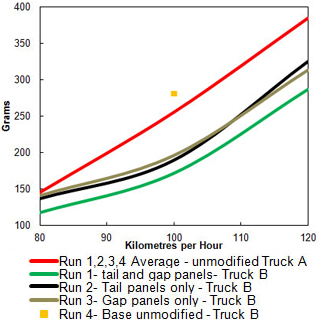

Run # 4 was driven at 100 kph to confirm that Truck A and Truck B had similar aerodynamic properties when unmodified. The Add-on panels were made of thin aluminum sheets, cut to form assumed aerodynamic shapes that fitted the modified Truck B. The shapes were not predetermined to be the most efficient. For this test the pieces were made to assume an aerodynamic shape. The pieces were held onto the Truck B using clear tape. The testing was done on a divided 4 lane highway with driver maintaining recording speeds of 80, 100 and 120kph for 2 to 3 minutes and a passenger for recording data. OBSERVATIONSThe data was recorded by observing Scale A attached to Truck A and Scale B attached to Truck B. The force was recorded as weight in grams on the scale and is shown in table 1. The chart 1 indicates the average for the readings from the 4 runs. When truck A and truck B were both base in run #4, the weight readings were very similar.

CONCLUSION This test was performed under less than ideal conditions using scaled model trucks and weigh scales while travelling on a public highway with vehicle turbulence and wind. It does however demonstrate that forces acting on objects going through air at highway speeds can be reduced by modifying the shape of the object. In a model truck/trailer combination travelling between 80 to 120 KPH

Further designing and testing of ideal shapes for the add-on panels could further improve the streamlining and lower the air resistance on the truck at highway speeds. The model trucks used had most aerodynamic improvements including truck side extenders, fairings and trailer skirts. The experiment indicates that closing the gap between the truck and trailer resulted in greater reduction of air resistance than the Kamm Tail. I assume the improvement to the frontal area is important to streamlining the air for the rear surfaces. Some of the creases on the tape holding the panels could have influenced the results. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||